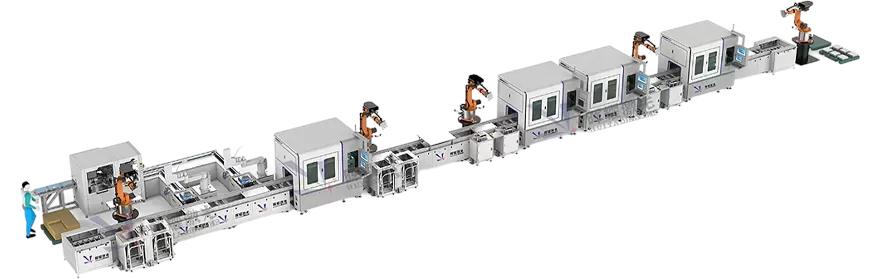

EV Smart Factory Solution

EV Battery Smart Factory Solution is an advanced, intelligent manufacturing system designed to enhance the production efficiency, quality, and safety of EV battery packs. By integrating automation, digitalization, and AI-driven technologies, the smart factory ensures high-precision manufacturing with minimal human intervention.

✅ Fully Automated Production – Reduces labor costs and improves consistency.

✅ AI & Big Data Integration – Enables real-time monitoring, predictive maintenance, and quality control.

✅ IoT & Digital Twin Technology – Simulates production processes for optimization.

✅ Flexible & Scalable Manufacturing – Supports different battery chemistries and pack configurations.

✅ Smart Quality Control System – AI-driven defect detection and automated testing.

Custom Built for Your EV Battery Assembly Line

High-Precision Automated Production for Prismatic, Pouch & Blade Batteries

Transform Your Battery Production with Intelligent Manufacturing

Huiyao Laser delivers end-to-end smart factory solutions for EV power battery modules and PACK assembly. Our advanced laser welding, robotic automation, and AI-powered inspection systems enable manufacturers to achieve:

✔ 30% higher productivity (up to 12PPM)

✔ Near-zero defect rates (99.8% yield)

✔ 70% lower labor costs through full automation

✔ Complete digital traceability with integrated MES

Industry-Leading Performance Metrics

Key Indicator | Traditional Line | Huiyao Smart Line | Improvement |

Cycle Time | 15s/module | ≤12s/module | 20% faster |

Welding CPK | <1.33 | ≥1.67 | 25% more consistent |

OEE | 75% | ≥86% | 11-point gain |

Energy Use | Baseline | 25% reduction | Significant savings |

Prismatic Battery Line

Fully automatic stacking (15s/module)

±0.1mm laser welding precision

1.5GWh/year single-line capacity

Pouch Battery Line

Auto edge folding & sealing

±0.2mm alignment accuracy

Integrated leak testing at 12PPM

Blade Battery CTP Line

Ultra-high-speed welding (0.3s/weld)

Structural integrity verification

12PPM throughput

Robotic Laser Welding Workstations

6-axis robots with ±0.02mm repeatability

10m/min welding speed with real-time QA

100% Inline Testing Systems

Electrical/mechanical/thermal validation

≤30s/module test cycle

Smart Factory MES

Real-time OEE monitoring

Full-process traceability (cell to PACK)

ERP/cloud integration

Precision Engineering

15+ years specializing in laser processing with:

Industry-best ±0.1mm welding tolerance

Adaptive parameter control for multi-chemistry support (LFP/NMC)

Turnkey Implementation

From design to commissioning in 6-9 months:

Customized line configuration

Mixed-production capability

≤72hr smart upgrades for existing lines

Global Support Network

24/7 remote diagnostics

On-site technical assistance

Operator training & preventive maintenance

Technical Requirements

Parameter | Specification |

Workshop Height | ≥6m |

Floor Load | ≥5 tons/m² |

Temperature | 22±2℃ |

Humidity | 45±5% RH |

Power Supply | 380V±10%, 50Hz |

Ready to Upgrade Your Battery Production?

Contact Us for a free needs analysis and customized quotation within 48 hours.

Q: Can you handle different battery formats on one line?

A: Yes – our flexible fixtures support prismatic/pouch/blade mixed production.

Q: What’s your typical project timeline?

A: 6-9 months from design to SOP, with ≤72hr downtime for retrofits.

Q: How is data security managed?

A: Military-grade encryption with role-based access controls in our MES.