ESS Smart Factory Solution

Energy Storage System (ESS) Smart Factory Solutions integrate advanced automation, digitalization, and artificial intelligence to enhance the production efficiency, quality, and safety of ESS battery modules and packs. These solutions encompass the entire manufacturing process, from battery cell production and module assembly to comprehensive testing, ensuring high-performance and reliable energy storage products. Implementing ESS smart factory solutions enables enterprises to lead in the rapidly evolving energy storage market, meeting diverse customer demands. These solutions not only enhance production efficiency and product quality but also reduce operational costs and strengthen market competitiveness.

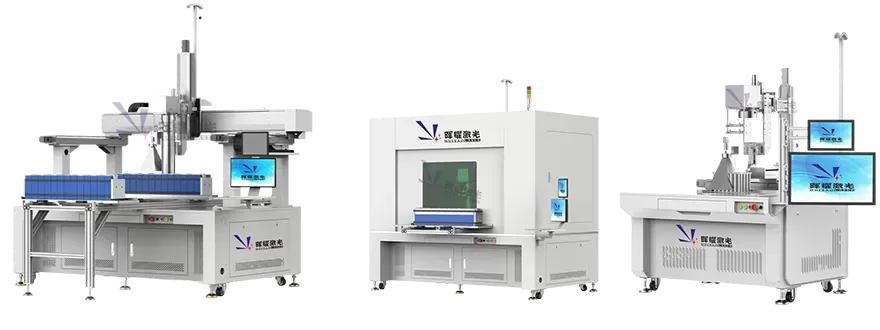

The ESS battery module and pack assembly line is a fully automated production system designed specifically for assembling energy storage battery modules and packs. This line employs cutting-edge technologies such as laser welding, automated assembly equipment, and intelligent inspection systems to guarantee the quality and consistency of each module and pack.

Key Features:

● High Automation: The assembly line automates processes from cell loading, module stacking, busbar welding, to pack assembly, minimizing manual intervention and boosting production efficiency.

● Precision Welding Technology: Utilizing laser welding ensures robust and reliable electrical connections within the battery modules and packs.

● Intelligent Inspection Systems: Integrated online inspection devices monitor product quality in real-time, ensuring compliance with design specifications and standards.

Ensuring the safety and reliability of energy storage systems necessitates rigorous testing of battery cells, modules, and packs during production. High-precision testing equipment provides accurate performance data, aiding manufacturers in optimizing product design and production processes.

Key Testing Equipment:

● Cell Cycling Test Systems: Evaluate the charge-discharge performance, capacity, and lifespan of battery cells, ensuring consistency and dependability.

● Module and Pack Charge-Discharge Test Systems: Assess electrical performance parameters such as voltage, capacity, and internal resistance of assembled modules and packs under various conditions.

● Environmental Adaptability Test Equipment: Simulate diverse environmental conditions—including temperature variations, humidity, and vibrations—to evaluate the stability and safety of battery products.

Precision Solutions for Industry Pain Points

As a pioneer in laser smart manufacturing, Huiyao Laser delivers:

50% efficiency boost with smart production lines (≤20s/pcs)

CPK≥1.67 guaranteed consistency

100% inspection for zero-defect delivery

Full-process digital twin management system

1. Laser Smart Production Systems

Proprietary laser welding technology (±0.15mm precision)

Integrated AI vision positioning

Supports 18650/21700 cylindrical cells production

2. Intelligent Inspection Platform

Equipped with Huiyao high-precision laser measurement

Ultra-fast 25s/module testing

Industry-leading 0.1-grade accuracy

3. Huiyao MES Smart Hub

Real-time production monitoring

Full lifecycle quality traceability

Smart early-warning system

Laser Technology Leader

10+ years laser process expertise

200+ technology patents

National high-tech enterprise certification

Global Project Experience

TÜV certified production lines (Europe)

UL safety certification (North America)

20+ successful projects in Southeast Asia

Performance Guarantee

Contractual OEE ≥87% commitment

99.4%+ yield rate promise

Verified 23% energy reduction